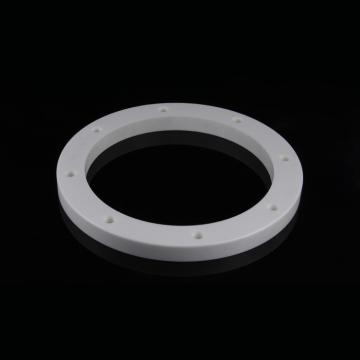

Ceramic Seals are multifunctional industrial Ceramic Components, mainly including ceramic sealing discs, sealing rings, gaskets, and ceramic valve balls. They are made of high-purity alumina, zirconia, Silicon Nitride, and silicon carbide, and other composite materials, these advanced ceramic materials boast exceptional wear, hardness, toughness, and chemical resistance. This versatility makes them ideal for many challenging applications.

Compared with sealing units with plastic and metal sealing cores, ceramic sealing units provide better sealing performance, reliability, work efficiency, and extended service life. You can learn about a few details from the following:

1. After grinding and polishing, the sealing contact surface has an ideal sliding surface with improved tribological for an ideal fluid seal.

2. Ceramic sealing parts are corrosion-resistant and will never oxidize in severe environments, ensuring the devices' longer service life.

3. All advanced ceramic seals have diamond-like hardness. For example, the wear resistance of alumina seals, which are most commonly used in household and sanitary seals, is 266 times that of manganese steel.

4. Among the raw materials of ceramic seals, silicon nitride ceramics with the lowest melting point than others are as high as 1900℃ and have a very low thermal expansion coefficient. For example, in automotive industries, the core sealing components will never be affected by ultra-high temperature.

5. Stable and consistent dimensional tolerances, especially after precision machining, the dimensional accuracy can reach the micron level, so the precise control of fluid dosage is particularly critical in medical applications.

Due to our over 15 years of expertise in Technical Ceramics and manufacturing know-how, we can design, prototype, and fabricate a wide range of standard and custom-made ceramic seals. If you are looking for ceramic components for sealing, please inquire now!

Commonly used materials in mechanical seals include hard alloy, graphite, PTFE, ceramic and rubber. The following table introduces their performance and applications.