Textile Ceramics refer to fine ceramics for textile machinery. They have the characteristics of high wear resistance, good chemical stability, and high content of new technologies. High-quality textile Ceramic parts are installed on critical parts of textile machinery and equipment, speeding up the manufacturing of synthetic fibers and yarns while improving their quality, winning the textile industry's favor for textile ceramics.

Ceramic materials commonly used to prepare textile parts can be divided into four major categories: alumina (Al2O3) ceramics, titanium oxide (TiO2) ceramics, zirconia (ZrO2) ceramics and zirconia toughened alumina (ZTA) ceramics.

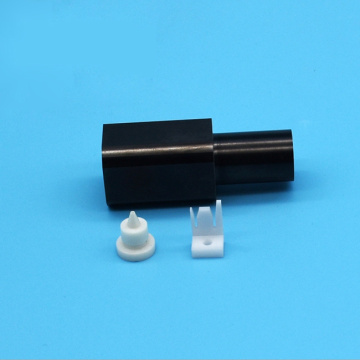

1. Alumina Ceramic is highly hard, has good chemical stability, is resistant to high temperatures and wear, and is highly wear-resistant. It can be used in winding, drawing, spinning, texturing, weaving, and knitting.

2. Titanium oxide ceramic has good wear resistance and antistatic effect and can be used in creels, texturing machines, winding machines, and coiling processes.

3. Zirconia Ceramic has good wear resistance, good chemical stability, high-temperature resistance, and high toughness and can be used in winders, texturing machines, and thread cutters.

4. Zirconia toughened alumina ceramic has high hardness, good wear resistance, good chemical stability, and certain toughness. It can be used in tensioners, thread cutters, winders, texturing machines, etc.