| Material | Flexural strength (MPa) | Fracture toughness (MPam1/2) | Thermal expansivity (10-6/K) | Thermal conductivity (W/m.K) | Dielectric strength (KV/mm) |

| Al2O3 | ≧380 | ≧4.3 | 6.6~7.5 | ≧24 | ≧15 |

| AlN | ≧450 | ≧4.0 | 4.4~4.8 | ≧180 | ≧17 |

| Si3N4 | ≧700 | ≧6.7 | 2.7~4.0 | ≧80 | ≧20 |

| ZrO2 | ≧800 | ≧6.5 | 8.0~9.5 | ≧3 | ≧10 |

| ZTA | ≧625 | ≧5.0 | 7.0~9.0 | ≧26 | ≧25 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

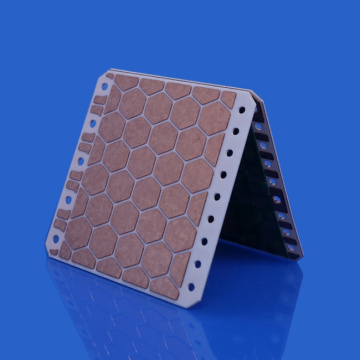

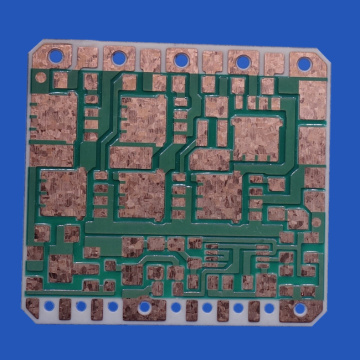

Here is our process flow.