Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Metallized Ceramic Substrates, also known as ceramic circuit boards, are obtained by metallizing the surface of the Bare Ceramic Substrate through technical means. According to different preparation principles and Ceramic Metallization processes, metallized ceramic substrates can be divided into two categories.

1. Planar Ceramic Substrate:

● TFC: Thin Film Ceramic Substrate ● TPC: Thick Printing Ceramic Substrate

● DBC: Direct Bonded Copper Ceramic Substrate ● DPC: Direct Plated Copper Ceramic Substrate

● AMB: Active Metal Brazing Ceramic Substrate ● LAM: Laser Activation Metallization Ceramic Substrate

2. Three-dimensional Ceramic Substrate

● HTCC: High-temperature Co-fired Ceramic Substrate ● LTCC: Low-temperature Co-fired Ceramic Substrate

● MSC: Multilayer Sintered Ceramic Substrate ● DAC: Direct Adhesion Ceramic Substrate

● MPC: Multilayer Plating Ceramic Substrate ● DMC: Direct Molding Ceramic Substrate

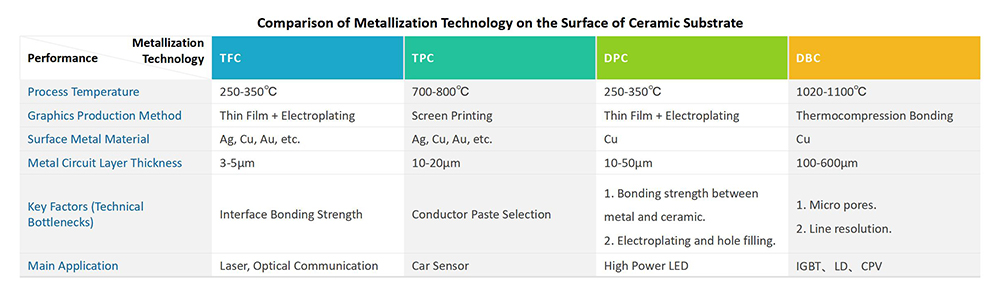

The following table is a comparison of several common metallized ceramic substrates.

We usually choose metal or ceramic substrates for heat dissipation of high-power semiconductor devices. As an emerging heat dissipation material, ceramic substrates have better thermal conductivity and insulation than metal substrates and are more suitable for power electronic product packaging. They have become fundamental materials for high-power electronic circuits' structural and interconnection technology. They are widely used in LED, automotive electronics, aerospace and military electronic components, lasers, and other industrial electronics.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.