Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

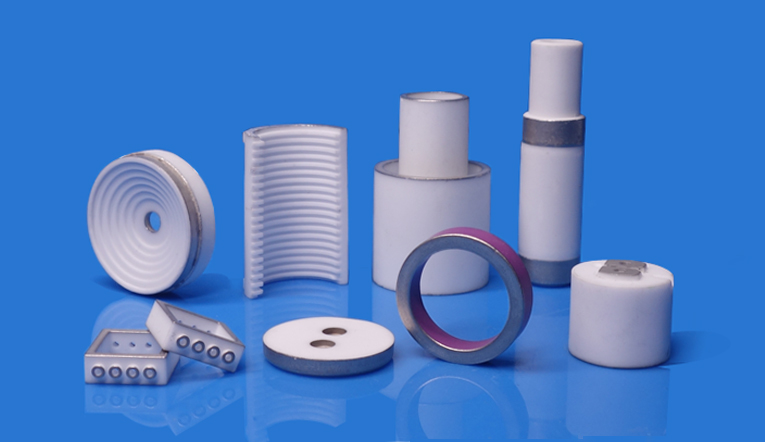

As the microstructure of the surface of advanced ceramic materials is different from the metal materials, brazing often does not happen from ceramic to metal to bond them directly. Therefore, the sealing of ceramic and metal is a special manufacturing process, namely Ceramic Metallization.

Firstly, a metallic layer will be applied on the ceramic surface of advanced Ceramic parts, afterwards, the surface of ceramic part has the properties of metal, then to achieve the welding of ceramic and metal. Currently, the ceramic metallization methods mainly include molybdenum manganese (Mo/Mn) method, active molybdenum manganese method,direct bonding copper(DBC) method, activated metal brazing method, Vacuum magnetron sputtering. In addition, ceramic and metal can be brazed directly via special glass solder.

1. Pretreatment: The specific ceramic surface to be ground to optical smoothing (the roughness better than Ra1.6), then cleaning the ceramic body in supersonic washing machine with acetone or alcohol for 20 minutes

2. Metallization paste formulating: weighting the compound according to specific formula, then grinding them to formulate the metallization paste with designated viscocity

3. Applying the metallization and drying: Deposite the metallization paste on ground ceramic surface by silk screen,sputtering, vacuum evaporation coating. Afterward, drying the metallization paste

4.Metallizing sintered reducing atmosphere: The process will be conducted in vacuum atmoshphere, mainly filled out hydrogen atmosphere

5. Electroplating or electroless plating: In order to increase the brazing wettability betweem ceramic and metal, a following metal coating will be covered on metallized layer via electroplating or electroless plating. The addtional plating would provent the ceramic metallization into oxidizing as well

6. Practical brazing:

The aim of ceramic metallization is to promote the ceramic to metal joining via brazing. It's an ideal method to check the gas tightness and brazing force via practical brazed subassembly.

7. Brazing force and leaking test

It's the final step to inspect the brazing force and leaking test for Metallized Ceramics.

January 19, 2022

January 03, 2017

December 09, 2023

August 12, 2022

November 06, 2024

November 07, 2024

Oxygen evolution reaction (OER) is an important half-reaction in energy conversion and storage devices such as electrolysis of water and secondary metal-air batteries. However, OER has a high...

With the rapid development of science and technology, and the continuous improvement of society, ceramic products and ceramic components at worldwide have present a rapid growth trend, which also...

1.Introduction Ceramic to ceramic or ceramic to metal joining have been using high vacuum technology, medical technology, electrical and sensor industries. Brazing is often the preferred method for...

Email to this supplier

January 19, 2022

January 03, 2017

December 09, 2023

August 12, 2022

November 06, 2024

November 07, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.