Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

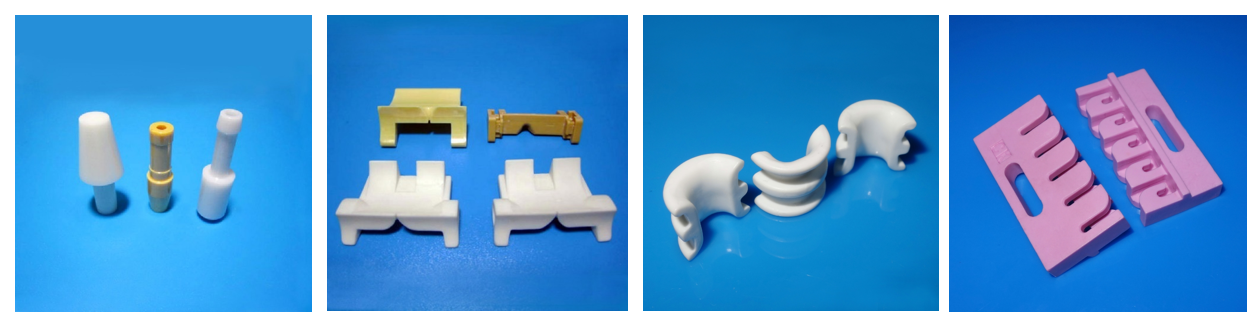

Starting in August 2016, our factory introduced a ceramic injection molding production line to manufacture Precision ceramics with precise size requirements. Injection molding technology is mainly used in the preparation of various engineering ceramics, such as ceramic brackets and ceramic posts for dental correction and restoration; Zirconia Ceramic ferrules and ceramic sleeves for optical communications; General Textile Ceramics such as nozzles, Ceramic Yarn Guides etc., bearing sleeves, gears, seals on various engineering ceramics; ceramic knives, ceramic watch chains and ceramic watch cases used in daily life.

Advantages of injection molding technology:1. The molding process has the characteristics of high degree of mechanization and automation, high production efficiency, short molding cycle, and high strength of the blank. The process can be precisely controlled (program control), making it easy to achieve large-volume and large-scale production;2. Form various small Ceramic parts with complex geometric shapes and special requirements, so that the sintered ceramic products do not need to be machined or require less processing, thereby reducing expensive ceramic processing costs;3. The formed ceramic products have extremely high dimensional accuracy and surface finish.

Advantages of injection molding technology:1. The molding process has the characteristics of high degree of mechanization and automation, high production efficiency, short molding cycle, and high strength of the blank. The process can be precisely controlled (program control), making it easy to achieve large-volume and large-scale production;2. Form various small Ceramic parts with complex geometric shapes and special requirements, so that the sintered ceramic products do not need to be machined or require less processing, thereby reducing expensive ceramic processing costs;3. The formed ceramic products have extremely high dimensional accuracy and surface finish.

Disadvantages: One-time equipment investment and processing costs are high, and it is only suitable for mass production.

January 19, 2022

January 03, 2017

December 09, 2023

August 12, 2022

November 06, 2024

November 07, 2024

As the microstructure of the surface of advanced ceramic materials is different from the metal materials, brazing often does not happen from ceramic to metal to bond them directly. Therefore, the...

1. In the raw materials, it breaks through the boundary of traditional ceramics with clay as the main raw material. Special ceramics generally use oxides, nitrides, silicides, borides and carbides as...

Oxygen evolution reaction (OER) is an important half-reaction in energy conversion and storage devices such as electrolysis of water and secondary metal-air batteries. However, OER has a high...

With the continuous development of science and technology, the progress of industrial ceramics has also made many breakthroughs,especially the research and development of multiphase composite...

Email to this supplier

January 19, 2022

January 03, 2017

December 09, 2023

August 12, 2022

November 06, 2024

November 07, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.